How the Zero Point Clamping System29 Revolutionizes Quick Changeovers in CNC Machining!

In the high-stakes arena of modern CNC machining, where precision, speed, and resource optimization are critical, reducing setup and changeover times has become a top priority for every machine shop. From small-batch prototyping to large-scale production runs, manufacturers are under constant pressure to get more done in less time — without compromising quality.

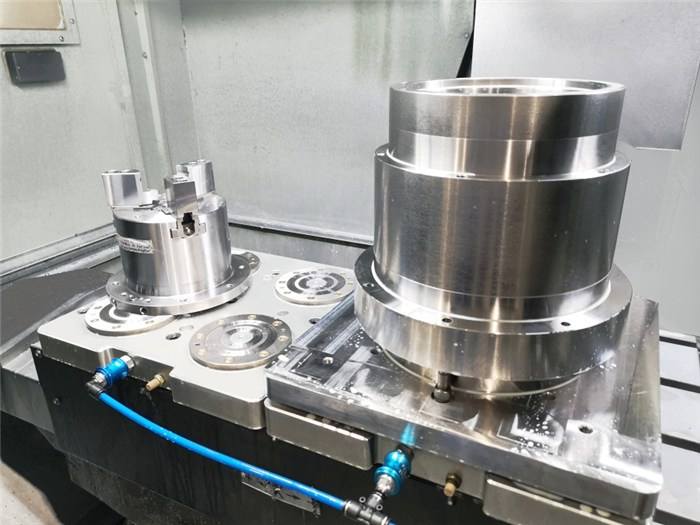

That’s why forward-thinking shops are turning to innovative workholding solutions like SilverCNC’s Zero Point Clamping System29 — a next-generation fixture solution designed to redefine efficiency across your machining processes. Whether you’re using 3-axis vertical milling or multi-axis horizontal machining centers, implementing zero point clamping technology can mean the difference between leading the market and lagging behind.

What Is a Zero Point Clamping System?

In traditional CNC setups, operators spend significant time manually aligning, clamping, and referencing fixtures for each job. These setups often involve using parallels, dowel pins, hand-tightened bolts, and manual measurements — a process that can take 30 minutes to several hours, depending on part complexity.

A Zero Point Clamping System (ZPCS) is a highly accurate, quick-change solution that eliminates these manual steps by using standardized clamping mechanisms (often spring-loaded or pneumatically/hydraulically actuated) that engage and locate fixtures or pallets at a defined 'zero point' on the machine table. Once installed, swapping out fixtures or pallets becomes a matter of seconds, not minutes or hours.

What Makes SilverCNC’s Zero Point Clamping System29 Unique?

At SilverCNC, we've designed the Zero Point Clamping System29 to go beyond the basics of fast-change technology. It offers:

📏 Sub-micron repeatability — Ideal for high-precision parts

⏱️ Changeover in under 60 seconds — Quickly clamp new fixtures or pallets

🧲 High holding force — Ensures rigidity during heavy-duty machining

🧰 Universal compatibility — Fits seamlessly with your existing machine table, tombstones, or rotary tables

💨 Pneumatic actuation — For quick release and clamping without manual bolts

🛠️ Modular interface — Accommodates a variety of fixture types and sizes

🟥 Hardened stainless steel clamping modules — Built for life on the production floor

The System29 is designed to meet the needs of both flexible job shops and high-volume production facilities, offering a scalable solution adaptable to a wide variety of CNC machines and fixture applications.

Benefits of the Zero Point Clamping System29 in CNC Machining

1. 🚀 Massive Reduction in Setup Times

The biggest win with the Zero Point Clamping System29 is time. Traditional machine setups require:

- Manual alignment

- Fixture leveling

- X-Y-Z reference setting

- Tightening bolts by hand

With System29, fixtures are aligned and clamped in less than 60 seconds, and repositioning is no longer necessary since every fixture is automatically returned to the exact same location. What was once a lengthy setup becomes an incredibly repeatable plug-and-play changeover.

2. 🎯 Unmatched Precision and Repeatability

Every clamp module in the Zero Point Clamping System29 is engineered to position fixtures within ±0.005 mm (5 microns). That level of repeatability means you can load a fixture, run a job, and reload it days or weeks later without losing zero reference.

This not only boosts quality control but enables lights-out machining where in-process probing and part adjustments are often unnecessary.

3. 💼 Standardization and Flexibility

System29 allows you to standardize your fixturing system across multiple machines and departments. That means less time customizing setups and more time running jobs. You can use common fixture bases or pallets for different machines, dramatically streamlining your manufacturing workflow.

Whether you use rotary tables, tombstones, or vertical CNC centers, SilverCNC's modular platform ensures smooth integration.

4. 🔁 Quick Palletization

Quick-change pallet systems compatible with System29 allow you to pre-load parts or fixtures offline. When the machine is ready, simply load the pallet into the clamps, press the button, and you’re machining — no manual alignment, operator skill, or probing required.

This enables concurrent operations that increase spindle uptime and total throughput.

5. ⚙️ Improved Machine Utilization

Every minute the machine is idle during setup is lost production time. Since System29 reduces changeovers to seconds, your spindle spends significantly more time cutting — translating to a higher overall equipment efficiency (OEE) and better return on investment.

Real-World Example: System29 in Action

Client: Apex Tooling Co. (Fictional Case Study)

Industry: Aerospace prototyping and production

Challenge: Setup times averaged 40 minutes per fixture change with 8 jobs/day

Solution: Integrated Zero Point Clamping System29 from SilverCNC across two VMCs

Results:

-Setup time reduced to 3 minutes per changeover

-Completed 3 additional jobs per shift

-Reduced operator fatigue and error

=Recouped cost of investment in less than 3 months

With SilverCNC’s zero point clamping system29, Apex Tooling scaled production without adding machines, simply by reclaiming downtime.

How the Zero Point Clamping System29 Works

-Base Module Installation:

Each system includes clamping modules mounted to the machine table or fixture surfaces with pre-engineered mounting holes.

-Fixture or Pallet Preparation:

Pallet bases include precision-located nipples or studs that mate perfectly with the clamping modules.

-Engagement:

A pushbutton or foot-pedal-activated pneumatic valve engages the clamps, pulling and locking the fixture into exact position.

-Operation Begins:

The system indicates clamping status with visual feedback (LEDs or sensors), and the machine is ready to run. Toolpaths do not require new zeroing or calibration.

System29 Compatibility & Integration

SilverCNC’s Zero Point Clamping System29 is universally compatible with:

-CNC vertical machining centers (VMCs)

-Horizontal machining centers (HMCs)

-4th/5th axis rotary tables

-Tombstone-based fixturing systems

-Modular grid plates and base stations

Our engineering support team provides custom bracketry and retrofit kits to ensure hassle-free integration, whether you’re upgrading an existing machine or designing a new workholding solution.

Engineering Support & Customization

Need something specific? SilverCNC offers:

-Custom clamp module spacing

-Modular base designs

-Dedicated pallets or fixture plates

-CAD models for CAM and simulation integration

-Technical consultation and automation support

-Best Practices for Maximum ROI

To get the most from your zero point clamping system29, follow these guidelines:

✅ Pre-load and stage your fixtures offline

✅ Use standard base plates and locating pins

✅ Train your operators on consistent clamping procedures

✅ Combine with probing cycles for in-process control

✅ Use for vertical and horizontal setups alike

✅ Plan fixture libraries for repeat production

Unlock the Power of Fast, Precise, and Scalable Fixturing

From dramatically reduced setup times and enhanced machine utilization to unbeatable repeatability and automation compatibility, System29 is not just a fixture system — it’s a foundation for smarter machining.

If you're serious about cutting costs, increasing throughput, and staying competitive, it's time to make the shift from traditional fixturing methods to Precision. Speed. Repeatability, with the Zero Point Clamping System29.

Frequently Asked Questions (FAQ)

1. How does the Zero Point Clamping System29 differ from traditional fixturing?

System29 eliminates manual alignment and clamping by enabling fixtures to be swapped quickly using location repeatability pins and automatic locking mechanisms controlled pneumatically.

2. Can I retrofit System29 to existing machines?

Yes. SilverCNC offers retrofit kits and engineer support for a wide range of machines including Haas, Mazak, DMG MORI, Fanuc, and more.

3. How accurate is the Zero Point Clamping System29?

System29 offers repeatability of ±0.005 mm, ensuring precision repeat setups every single time.

4. Is System29 suitable for automated machining environments?

Absolutely. It’s designed for integration with robotics, pallet changers, and in-process probing, making it ideal for lights-out manufacturing and high-volume production lines.

5. What is the holding force of the clamp modules?

Each clamp offers holding forces upwards of 25,000 N to resist heavy machining loads, ensuring both safety and performance.

6. Can I use my existing fixtures with System29?

Yes, we offer modular adapter plates that convert existing fixtures into System29-compatible pallets with little to no modification.

7. Does SilverCNC provide CAD files for CAM integration?

Absolutely. All System29 components are available as STEP and IGES files, enabling seamless CAM simulation and fixture verification.

Comments

Post a Comment