How to Maximize Tool Life and Precision with a Tool Setter Probe!

In today’s fast-paced, high-precision manufacturing environment, machine shops are under growing pressure to deliver superior part quality while maintaining competitive production speeds. As margins tighten and scrap reduction becomes more urgent, maximizing tooling efficiency is not just a goal—it’s a necessity. One of the most effective, yet often underutilized, technologies in achieving this is the tool setter probe.

At SilverCNC, we specialize in intelligent automation products that help streamline CNC operations, reduce downtime, and improve repeatability across a wide range of industries. Among our most impactful solutions is the tool setter probe, an essential device engineered to monitor, measure, and protect your tooling investment while enhancing cutting precision.

Why does this matter?

Because even a minor inconsistency in tool length, diameter, or wear can lead to machining inaccuracies, tool breakage, flawed parts, or costly rework. Manual measurement techniques are often slow, susceptible to human error, and interrupt the production process. By contrast, a tool setter probe performs automatic, real-time assessment of your tools directly inside the machine—ensuring that every cut starts with confidence.

What Is a Tool Setter Probe?

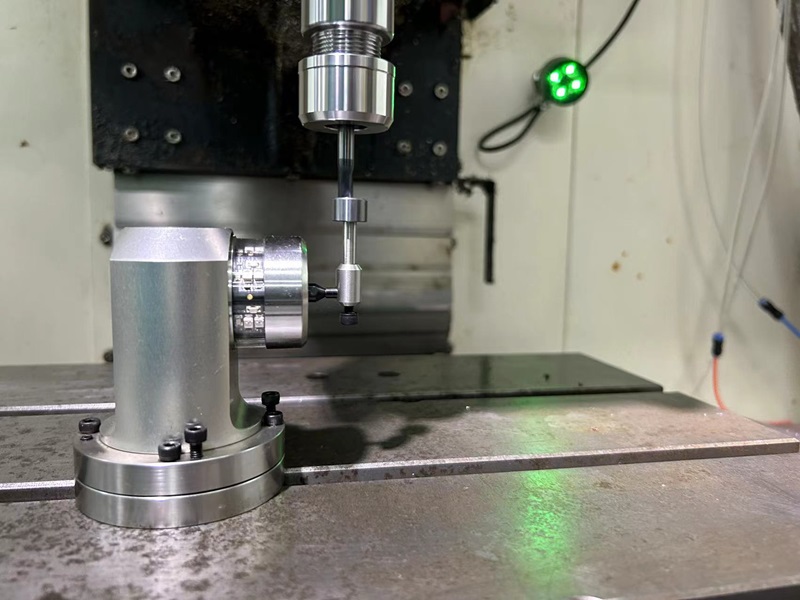

A tool setter probe is a high-precision device mounted inside a CNC machine that automatically measures tools’ physical characteristics—primarily length, diameter, and wear condition. It operates by having the cutting tool make contact with a stylus on the probe device, which then registers the exact position or deviation. That data is transmitted to the CNC controller, which adjusts offsets or triggers alerts based on defined thresholds.

Essentially, a tool setter probe automates:

- Tool length measurement

- Tool diameter compensation

- Breakage detection

- Wear monitoring during production

- Offset adjustment for tool changes

This functionality is invaluable for ensuring that each tool is set accurately before machining begins and that problems are detected early—before they cause costly downtime or scrap.

Tool setter probes can be contact-based (touch-trigger), optical, or laser-based, with each offering different benefits based on the application type.

Benefits of Using a Tool Setter Probe

Implementing a tool setter probe isn’t just about measuring tools—it’s about redefining operational efficiency. Here’s how it unlocks greater value across your production process:

✅ 1. Extended Tool Life

Chipping or dulling tools often go unnoticed during operation and continue cutting until failure. A tool setter probe can detect tool wear early and prompt replacements before damage occurs, thus extending usable life and protecting your investment.

✅ 2. Guaranteed Tool Accuracy and Repeatability

Each time a tool is exchanged, even slight variations in length or diameter can result in dimensional errors. The probe defines exact tool geometry and automatically updates CNC offsets, ensuring every tool performs identically—even across shifts or different machines.

✅ 3. Increased Machine Uptime

Manual touch-offs take time—minutes per tool, multiplied by hundreds of tools in batch operations. A tool setter probe completes measurements in seconds, reducing idle time and increasing machine utilization.

✅ 4. Real-Time Breakage Detection

High-speed machining environments put tools under tremendous stress. Probes check the tool between cuts or after critical operations to ensure it's intact. If a break is detected, the machine can stop automatically or load a backup, saving expensive parts from unnecessary damage.

✅ 5. Reduction in Scrap and Rework

When tool length or diameter is off by even fractions of a millimeter, part tolerances suffer. By keeping tools perfectly referenced, the tool setter probe helps maintain tight tolerances and improve first-pass yield rates.

Common Industry Applications

The benefits of tool setter probes extend across a variety of industries:

🛩️ Aerospace Manufacturing

-Ultra-precise components demand tight repeatability

-Costly exotic materials require tear-free tool cutting

🚗 Automotive Production

-High-volume tool changes necessitate fast, automatic setup

-Consistency in parts across production lines is essential

💊 Medical Device Manufacturing

-Micron-level tolerancing and sterile environments require non-contact or sealed probes

-Complex geometries demand flawless tool dimensions

🏭 Mold & Die Shops

-Tool offsets for deep cavities and contouring must be exact

-Avoiding tool collisions in tight areas is critical

🔧 General CNC Machining

-Shops benefit from faster job changes and fewer manual errors

-Essential for shops managing multiple machines and operators

How to Choose the Right Tool Setter Probe

When selecting a tool setter probe for your CNC operation, consider the following factors:

1. Type of Probe

-Contact (Touch Trigger): Most common; suitable for most applications

-Laser Tool Setter: Offers non-contact, high-precision measurement for delicate or micro tools

-Optical Probes: Work without physical contact; ideal for cleanroom and sensitive operations

2. Positioning

Determine whether the probe will be table-mounted, tower-mounted, or swing-arm style. This depends on machine space, tool length, and how many tools you regularly use.

3. Machine Compatibility

Ensure compatibility with your CNC controller (FANUC, Siemens, Heidenhain, Mitsubishi, etc.). All SilverCNC probes include compatibility documentation and support.

4. Environmental Resistance

Choose probes designed for your shop’s environment. SilverCNC probes come with IP-rated enclosures, coolant resistance, and industrial sealing suitable for high-volume production.

5. Integration and Software

Probes must communicate efficiently with the controller. Look for systems that support G-code integration, probing macros, or conversational programming support.

Implementation Tips for Maximizing Returns

To get the most from your tool setter probe, follow these best practices:

1. Calibrate Regularly

Even with automated systems, calibration ensures consistent readings. Most shops recalibrate daily or weekly depending on usage.

2. Integrate into Workflows

Program automatic tool checks into job routines. Consider checking tools at set time intervals or after specific operations.

3. Train Operators

Ensure your team understands probe function, tool offset logic, and troubleshooting basics for maximum benefit.

4. Monitor Wear Patterns

Use probe data to track the lifespan of different cutters or materials. This allows for better tooling decisions and planned replacements.

SilverCNC Tool Setter Probe Highlights

Why choose SilverCNC for your probe solution?

✅ Ultra-rugged, long-life styluses

✅ High-speed contact and laser models available

✅ Seamless integration with all major CNC platforms

✅ Real-time break detection systems

✅ Full documentation, installation help, and technical support

Thousands of manufacturers across multiple industries rely on SilverCNC to keep their machines smarter, faster, and more accurate.

Smarter Measurement, Longer Tool Life

In today’s precision-driven manufacturing world, guessing is no longer an option. Manual tool measurement is time-consuming, error-prone, and costly. By contrast, a tool setter probe empowers your CNC machine with the intelligence to measure, verify, and adjust—automatically and accurately.

With tools at peak performance and wear issues caught before they become problems, your shop can achieve lower scrap rates, improved cycle times, and extended tooling life—all from one smart device.

FAQs:

❓ What is the main difference between a tool setter probe and a machine tool probe?

A tool setter probe measures tools (length, diameter, breakage), while a machine tool probe measures workpiece dimensions and locations. Both work together to optimize machining precision.

❓ Can a tool setter probe detect broken tools during runtime?

Yes. Most models offer real-time or periodic break detection. If a tool breaks mid-process, the controller can be programmed to stop the cycle, alert the operator, or swap in a backup tool.

❓ Will a probe work with older CNC machines?

Yes—in most cases. Our SilverCNC support team can assist with retrofitting probes to older machines, provided the controller supports I/O or probing cycles.

❓ Does a tool setter probe require frequent maintenance?

Minimal maintenance is needed. Keep the contact surface clean, check wiring for fatigue, and recalibrate occasionally. Lasers may require lens cleaning.

❓ How accurate are SilverCNC probes?

SilverCNC probes offer repeatability down to ±1 micron, depending on the model. This is more than sufficient for high-precision machining applications.

❓ Can I use the same probe for all my toolholders?

Yes. Tool setter probes measure the cutting tool itself, regardless of toolholder type. For systems with extreme size variation, custom calibration profiles may help.

Comments

Post a Comment