How to Get Perfect Support Every Time with a Manual Tailstock!

In machining, nothing undermines accuracy quite like instability. Whether you’re turning long shafts, cylindrical workpieces, or running high-speed rotary operations, proper workpiece support is critical for achieving precision, minimizing deflection, and ensuring tool longevity. That’s where a Manual Tailstock becomes an essential tool in your CNC or manual machining setup.

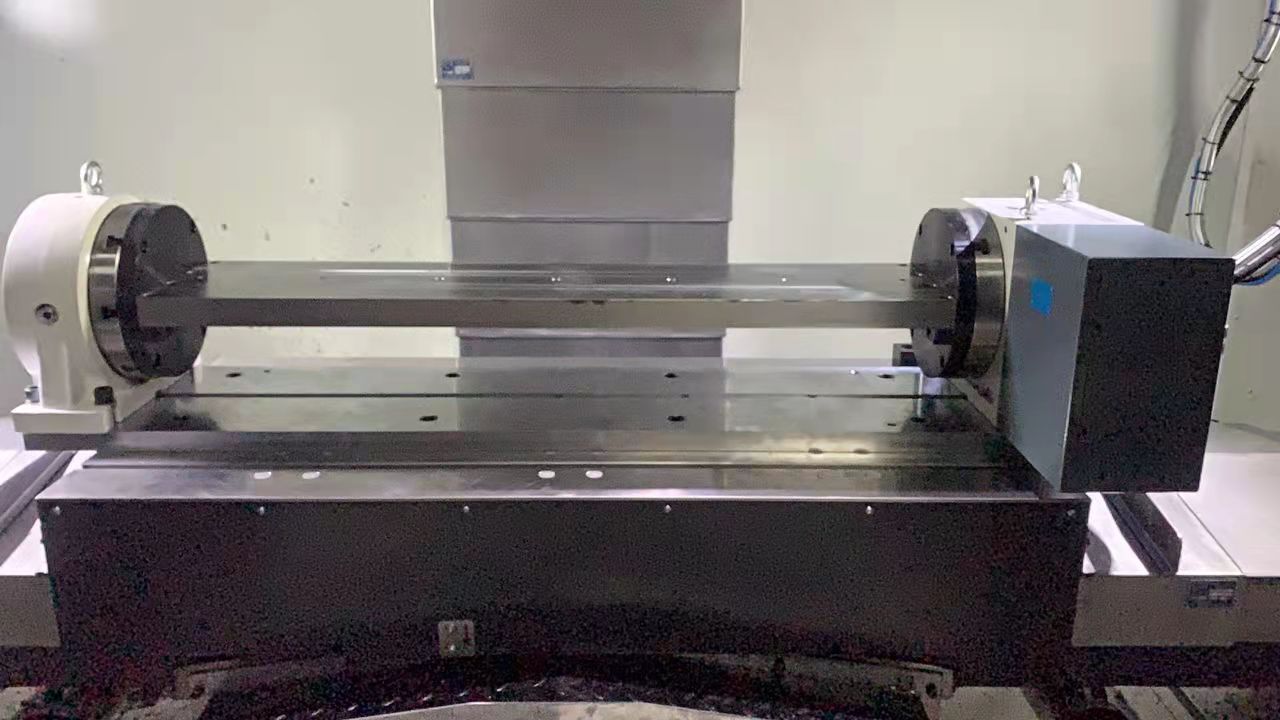

At SilverCNC, we work closely with shops of all sizes to provide durable, high-performance accessories that truly enhance machining performance. One of the simplest—yet most effective—add-ons to your rotary table, lathe, or 4th axis setup is the manual tailstock. Known for its straightforward operation and strong support capabilities, it plays a vital role in output quality, especially when you're working with long or slender components that are prone to vibration or bowing.

Yet, the efficiency and precision of a manual tailstock depend on:

- Selecting the correct type

- Proper installation and alignment

- Adjusting the unit per each machining requirement

- Consistent maintenance and use best practices

What is a Manual Tailstock?

A manual tailstock is a mechanical device typically mounted on the opposite side of a lathe or rotary table from the spindle. Unlike automatic or hydraulic tailstocks, the manual version requires the user to position and adjust it manually.

It typically consists of:

- A main body/base that slides or mounts on the machine bed

- A quill (or barrel) that extends and retracts using a handwheel

- A center or live point that makes contact with the workpiece

- Optional features like locking mechanisms or height adjustment points

The primary role of a manual tailstock is to support the free end of a rotating or long workpiece, preventing deflection, vibration, or runout during machining.

Why Use a Manual Tailstock?

While it may appear basic, a manual tailstock is a highly strategic component in CNC and manual machining. Using one can tremendously improve job outcomes in terms of dimensional accuracy, surface finish, and tool longevity.

Let's explore the key reasons:

✅ 1. Reduces Workpiece Deflection

Long or thin parts naturally tend to bend or wobble during machining due to cutting forces, especially at high RPMs. A tailstock provides counter-pressure that prevents part movement.

✅ 2. Improves Surface Finish

Vibrations and chatter caused by unsupported workpieces often result in poor surface finishes. A tailstock stabilizes the component and ensures smoother tool engagement.

✅ 3. Maintains Concentricity and Tolerances

Accurate support on the tail end means that both ends of the workpiece rotate on the same centerline—critical when precision tolerances are required.

✅ 4. Prevents Tool Breakage

With less deflection and vibration, the cutting tool remains properly aligned and under consistent load—while reducing the chances of chatter and premature failure.

✅ 5. Enhances Safety

Parts coming loose or whipping during turning operations can be hazardous. A secured tailstock holds the workpiece firmly in position, minimizing safety risks.

Where is a Manual Tailstock Used?

Manual tailstocks are commonly used across different setups, including:

- Lathes (manual or CNC) for turning long shafts and bar stock

- CNC rotary tables when machining long components in conjunction with a 4th axis

- Horizontal milling machines to support round or tubular workpieces

- Grinding operations in cylindrical and centerless grinding setups

SilverCNC tailstocks are engineered with industry-grade materials, making them suitable for both light-duty and heavy-duty machining tasks.

Choosing the Right Manual Tailstock for Your Setup

Here’s what to consider:

🛠 1. Center Height

Make sure the center height of the tailstock (distance from base to center point) matches that of your rotary table or lathe spindle. Mismatched heights can lead to inaccurate support and accelerated wear.

🧱 2. Tailstock Body Style

Choose between:

- Fixed base tailstocks: For setups where you don’t need regular adjustments

- Sliding tailstocks: Offer versatility and repositionability across various job lengths

🎯 3. Quill Stroke and Locking

Check the quill (barrel) extension length and ensure it includes a fine-adjustment handwheel and a locking mechanism to hold it firmly during operation.

🧰 4. Center Type

- Dead center: Fixed and requires lubrication

- Live center: Includes its own bearings and rotates with the workpiece—ideal for high speeds

🔩 5. Mounting Options

Ensure the tailstock can be securely mounted on your machine's T-slots or baseplate system. The more rigid the mount, the better the support.

How to Set Up Your Manual Tailstock for Perfect Support

A manual tailstock is only as effective as how well it’s installed and aligned. Follow these steps for reliable performance:

✔️ Step 1: Set It at the Correct Height

Use a dial indicator or gauge block to confirm the center height matches your spindle or rotary table. Some tailstocks come with adjustable bases to fine-tune the height.

✔️ Step 2: Align with the Center of Rotation

Slide the tailstock into position and use a sharp-point dead center or test indicator to align it coaxially with your part axis. Any misalignment can cause poor finishing or excessive wear.

✔️ Step 3: Secure the Base

Use bolts or clamps to lock the tailstock onto your machine bed or fixture plate. Ensure no lateral movement.

✔️ Step 4: Adjust the Quill

Carefully advance the quill with the handwheel until it contacts the center-drilled hole in your part, then lock it into position.

✔️ Step 5: Test the Setup

Manually rotate the spindle to ensure the workpiece runs true, and perform light test cuts or check concentricity with an indicator probe.

Common Mistakes to Avoid When Using a Manual Tailstock

Even experienced machinists can overlook these critical areas:

❌ Using the Wrong Center Height

Always double-check the center alignment before beginning machining. If your tailstock is off by even 0.5 mm, you'll get deflection and uneven wear.

❌ Over-tightening the Quill

Applying too much pressure with the tailstock quill could deform the workpiece or load up the machine unnecessarily.

❌ Forgetting to Lock the Quill

An unlocked quill can move during cutting, defeating the purpose of the tailstock altogether.

❌ Low-Quality or Worn Centers

Old, rusted, or dull centers will not provide peak performance and may damage the material or leave burrs.

Tips to Get the Most Out of Your Manual Tailstock

- Use live centers for high-speed operations to minimize wear and heat

- Keep your centers clean and lubricated for reduced friction

- Store the tailstock in a tool rack or cover it when not in use

- Use matched accessory sets like Silvercnc’s rotary table + tailstock kit for guaranteed compatibility

- Perform routine inspections for alignment, quill movement smoothness, and locking function integrity

Why Choose Silvercnc Manual Tailstocks?

- Hardened steel construction for long life

- Micrometer-style handwheels for accurate adjustments

- Interchangeable centers (dead or live)

- Options for various center heights to fit all major rotary tables and CNC setups

- Quick-ship solutions for urgent upgrades or replacement needs

We back our tailstocks with easy-to-follow guides, technical drawings, and application support to ensure you’re confident from unboxing to production.

Support Your Precision with Confidence

In machining, stability is accuracy. No matter how sophisticated your CNC setup is, unsupported workpieces will always introduce risk—risk of error, scrap, and downtime.

A manual tailstock is a simple yet invaluable addition to your machine shop. It protects your tooling, secures your workpiece, and ensures everything runs true from the first cut to the last.

Frequently Asked Questions (FAQ)

Q1: Do I need a tailstock on every job?

Not necessarily. A tailstock is mainly required when turning long, thin, or flexible workpieces that could bend or vibrate. For short or rigid parts, it may not be needed.

Q2: What's the difference between a manual and hydraulic tailstock?

A manual tailstock is adjusted and clamped by hand. A hydraulic tailstock uses hydraulics for automatic positioning—ideal for high-volume or CNC lathe manufacturing. Manual versions are simpler, more affordable, and ideal for general use.

Q3: How do I know if my tailstock is aligned?

Use a dial test indicator on a test bar or dead center to verify that the tailstock point aligns perfectly with the spindle centerline over a certain distance.

Q4: Can I upgrade my existing rotary table with a Silvercnc tailstock?

Yes! Silvercnc tailstocks are built to match our rotary table heights, but we also offer custom height adjustments and fitment kits for third-party rotary tables.

Q5: What type of center should I use?

-Use a dead center for low-speed operations or where a steady rest is involved.

-Use a live center for high-speed turning and smooth rotation. Choose one rated for your RPM and load.

Comments

Post a Comment