How CNC Workholding Fixtures Improve Accuracy, Speed, and Safety!

In modern manufacturing, the push for tighter tolerances, faster production, and safer machining environments has never been more intense. As CNC machines evolve in complexity and capability, so too must the way parts are secured during machining. At the core of this essential foundation lies a crucial element that often determines the success—or failure—of the entire process: CNC Workholding Fixtures.

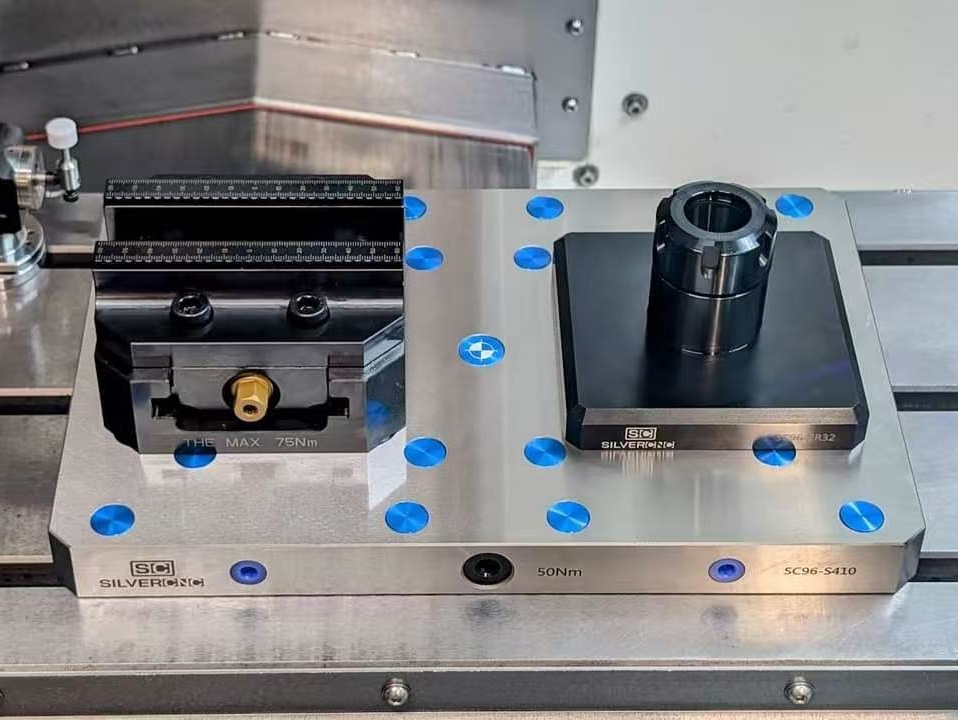

At SilverCNC, we specialize in intelligently engineered CNC workholding fixtures that help manufacturers unlock greater efficiency, precision, and operational safety. Whether you’re producing aerospace components, high-volume automotive parts, or custom-made medical devices, the right fixture can make all the difference in outcomes.

What Are CNC Workholding Fixtures?

CNC workholding fixtures are custom or standardized devices designed to hold, support, and locate a workpiece securely during machining operations. Their purpose is to ensure the workpiece does not move, vibrate, or shift under forces generated during cutting, milling, drilling, or turning processes.

These fixtures are mounted onto the CNC machine bed or table and are engineered to maintain repeatability and precision over single or multiple-part runs.

Key Roles of CNC Workholding Fixtures:

- Secure the workpiece immovably

- Maintain exact orientation and alignment

- Distribute clamping pressure evenly

- Facilitate quick loading/unloading

- Reduce operator dependency and manual alignment errors

Why CNC Workholding Fixtures Matter More Than Ever

As manufacturing landscapes grow more competitive, machine shops are under pressure to do more with less—less time, less margin for error, and less labor cost. Here’s why investing in smart CNC workholding Fixtures has become a strategic advantage:

✅ Precision & Repeatability

With CNC tolerances becoming narrower, a part must sit in exactly the same position every time. A high-quality fixture removes variability and improves output consistency even on the most geometrically complex parts.

⚡ Speed & Efficiency

Fixtures reduce time lost in setup, alignment, and rework. Streamlined workholding methods allow operators to change parts quickly. Some even use quick-clamp or zero-point systems that minimize machine idle time.

🔒 Workplace Safety

Incorrect clamping is one of the leading causes of tool failures and accidents. By providing uniform and secure clamping, CNC workholding fixtures increase safety for both the operator and the machine.

Types of CNC Workholding Fixtures

The ideal fixture depends on the part geometry, material, machining operation, and batch volume. Common types include:

🔹 Vise Fixtures

Ideal for smaller or block-shaped parts. Can be configured into multi-part holding systems.

🔹 Custom Plates & Jigs

Machined or fabricated based on specific part profiles. Great for irregular shapes or contour-based features.

🔹 Modular Fixture Systems

Highly flexible setups using standardized elements like pins, clamps, stops. Suitable for low to medium volume and prototype machining.

🔹 Vacuum Fixtures

Use suction to hold flat or non-ferrous parts. Common in aerospace and composite materials where mechanical clamping could cause deformation.

🔹 Magnetic Fixtures

Used primarily for ferrous materials, allowing quick setup without traditional clamps.

🔹 Hydraulic/ Pneumatic Fixtures

Automation-friendly options for high-volume production. They offer the fastest cycle times and consistent clamping force.

At SilverCNC, we design and manufacture customized CNC workholding fixtures for all of the above use cases and can tailor solutions to virtually any industry requirement.

How CNC Workholding Fixtures Improve Machining Accuracy

The most direct benefit of proper workholding is precision. Here’s how:

🎯 Positioning Control

Fixtures ensure parts are located using reference datums—reducing deviations and establishing precise coordinate systems.

🔩 Clamping Pressure Consistency

Over- or under-tightening with manual vises can deform parts. Dedicated fixtures distribute uniform pressure, minimizing part distortion.

💡 Simultaneous Multi-Side Machining

Some fixtures enable access to all sides of the workpiece in a single setup—reducing re-fixturing and justifying 4- or 5-axis machining operations.

🛠️ Minimal Tool Deflection

A rigidly held part offers stable engagement conditions for cutting tools, enhancing tolerances and surface finish.

Improving Speed and Throughput with Workholding

CNC workholding fixtures offer a strong return on investment when it comes to increasing manufacturing speed:

🔁 Reduced Setup Time: Standardized fixtures reduce alignment and measurement steps between parts.

📦 Batch Processing: Multi-part holders allow several units to be machined simultaneously.

🔧 Fewer Reworks: Precision holding reduces workpiece misalignment, decreasing the chance of tolerance rejections.

🤖 Automation Compatibility: Pneumatic and hydraulic fixtures integrate with robotic material handling systems, enabling lights-out or unmanned production.

Enhancing Safety with Secure CNC Workholding

In high-speed and high-torque machining scenarios, part ejection is a real risk. Fixtures:

-Prevent parts from flying off the table

-Minimize tool breakage due to vibration or movement

-Protect the spindle and body of your CNC machine

-Lower the chance of operator injuries during setup or operation

SilverCNC fixtures are tested under load-bearing conditions and designed to eliminate slippage or creep, even under extreme cutting forces.

Specialized CNC Workholding for Industry Applications

🔬 Medical Devices

Ultra-fine finish and microscopic accuracy demand custom-positioned, low-force clamps that protect delicate surgical and implant parts.

✈️ Aerospace

Lightweight materials like aluminum and titanium benefit from vacuum-based or soft-jaw custom fixtures that prevent deformation.

🚗 Automotive Mass Production

Hydraulic fixtures clamp components like pistons, rods, gears in seconds for rapid production across thousands of units.

🛠️ Tool & Die

Complex 3D cavity parts rely on modular and 5-axis adaptive fixtures for uninterrupted tool access.

Also Read: Applications of CNC Workholding Fixtures

How to Choose the Right CNC Workholding Fixtures

Choosing the best fixture comes down to answering the following:

- What is the part geometry? – Simple blocks vs. curved, asymmetrical parts

- How many parts per batch? – One-off prototypes or long-run production

- What tolerances are required? – High-precision work may need rigid, custom positioning

- What material are you machining? – Fragile, soft, or ferrous materials each require different clamping pressures and systems

- Machine compatibility – Ensure fixtures match your CNC table size, travel range, and controller capabilities

SilverCNC experts offer free consultations for matching your requirements with the ideal workholding solution.

Maintenance and Best Practices for CNC Fixtures

To maximize performance and longevity:

🧽 Clean fixtures between setups to remove chips and swarf

🔧 Check locking systems and clamps for wear or fatigue

🛠️ Re-calibrate fixture positions periodically

🔩 Tighten bolts with calibrated torque wrenches

🎯 Re-measure datums and offsets after each changeover

Case Study – CNC Shop Triples Output with SilverCNC Fixtures

🏭 Client: Electronics Component Manufacturer – Taiwan

Challenge: Time-consuming setup, high scrap rate, inconsistent finishes

Solution: SilverCNC designed modular 4-station fixture plates with zero-point automation

Results:

-180% productivity increase

-Setup time reduced by 65%

-First-pass yield improved to 98.9%

-ROI achieved in just 5 months

Work Smarter with Workholding

Precision in CNC machining is not just about the machine or the tool—it’s about how the part is held during those critical moments of contact. As complexity increases and cycles shorten, CNC Workholding Fixtures emerge as one of the smartest investments you can make.

FAQ –

Q1: Can fixtures be used on both mills and lathes?

Most CNC workholding fixtures are designed for a specific type of machine, though modular-mount versions can be adapted to both with proper interfaces.

Q2: How do I know if I need a custom fixture?

If your parts exhibit inconsistent tolerances, require frequent repositioning, or have complex geometries, a custom fixture is often the best choice.

Q3: Are vacuum fixtures safe for heavy parts?

Vacuum fixtures are best for flat, lightweight parts. For heavier items, mechanical or hydraulic systems are safer and more stable.

Q4: What’s the average cost of a CNC workholding fixture?

Basic modular setups may start around $500–$2,000. Fully customized, multi-part fixtures can range $5,000–$20,000, depending on complexity.

Q5: How do I align and calibrate a new fixture on my CNC machine?

Use touch probes, dial indicators, or laser alignment systems. SilverCNC provides setup guides and alignment tools for every fixture model sold.

Q6: Can I use my CNC software to simulate the fixture placement?

Yes, many CAM software platforms allow importing 3D fixture models to check for collisions and tool access. We provide CAD files for all our designs.

Q7: Are SilverCNC fixtures compatible with zero-point systems?

Absolutely. We offer base plates and clamp systems that integrate with popular zero-point solutions like Erowa, System 3R, and Lang.

Comments

Post a Comment